Precision Machine of Savannah utilizes state of the art large stationary Coordinate Measuring Machines (CMM’s) and touch-probe digital height gages to perform precise measurements of key characteristics and critical features based on customer engineering requirements. Along with having the capabilities to perform GD&T requirements, our inspection department is able to perform all necessary inspection requirements including surface finish, coating thicknesses, TIR characteristics, and a multitude of various dimensional features. These inspections are performed in a temperature and humidity-controlled quality lab.

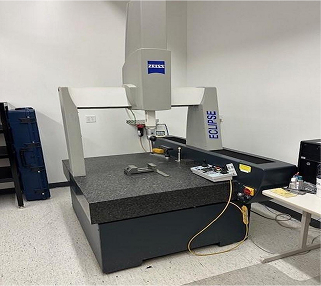

Global S 154010 Blue CMM

PC-DMIS SOFTWARE CONTROLLED

MAX WORK AREA

Travel: X54.00,Y155.00,Z36.00