PART IDENTIFICATION DEPARTMENT

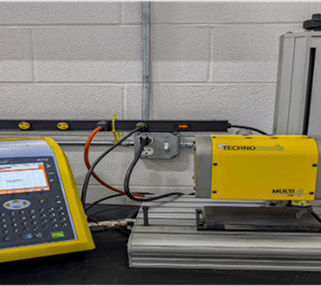

DOT PEEN MARKING

SHALLOW AND DEEP ETCHING

INK JET PRINTING

PMS provides dot peen marking which is ideal for permanent marking with advantages like precise and fast marking, adaptability to various materials, and repeatability, all of which contribute to durable engravings. It guarantees permanent markings with adjustable depth, tailored to meet specific needs and desired outcomes.

PMS also provides shallow etching which is very fast – a mark is typically produced in less than a second. The impression is dark in color, the degree of which depends on a number of factors including the base metal. Some stainless-steel yields only a dark brown mark, whereas Monel can produce a jet-black mark with the proper electrolyte.

PMS also provides deep etching which can produce an etch in the range of .001 – .006 deep. We utilize the appropriate stencil material, etching pad, and the material-specific electrolyte so that the base material can be removed without molecular deformation into the part being etched.

PMS also provides ink jet printing which produces a part marking that is reliable and predictable, providing consistent print quality and minimizing the risk of errors or problems. Advantages include automatic cleaning and drying, smart startup, automatic ink particle optimization, and reduced downtime and operating costs.