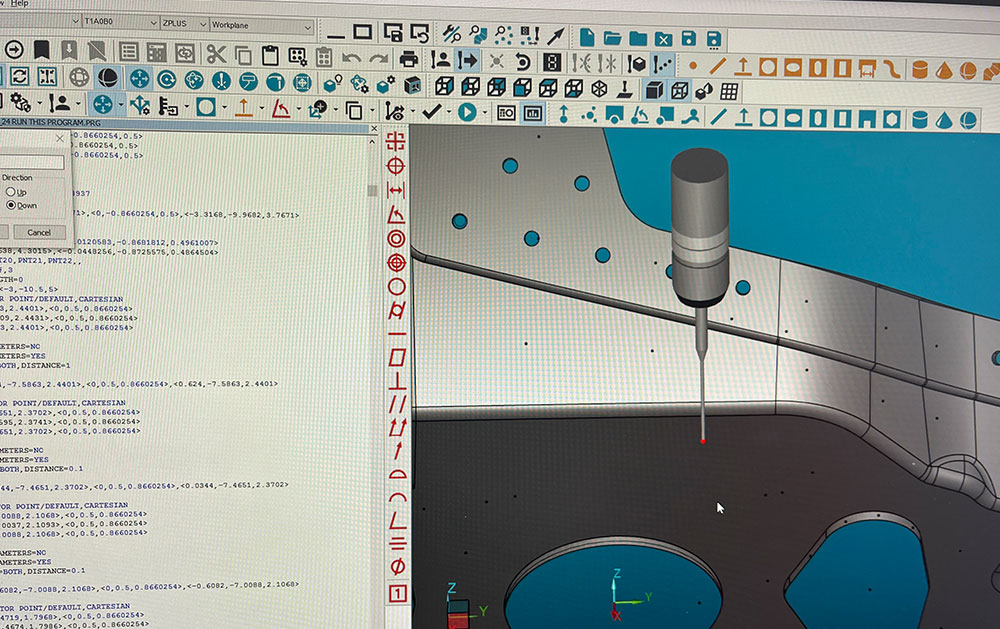

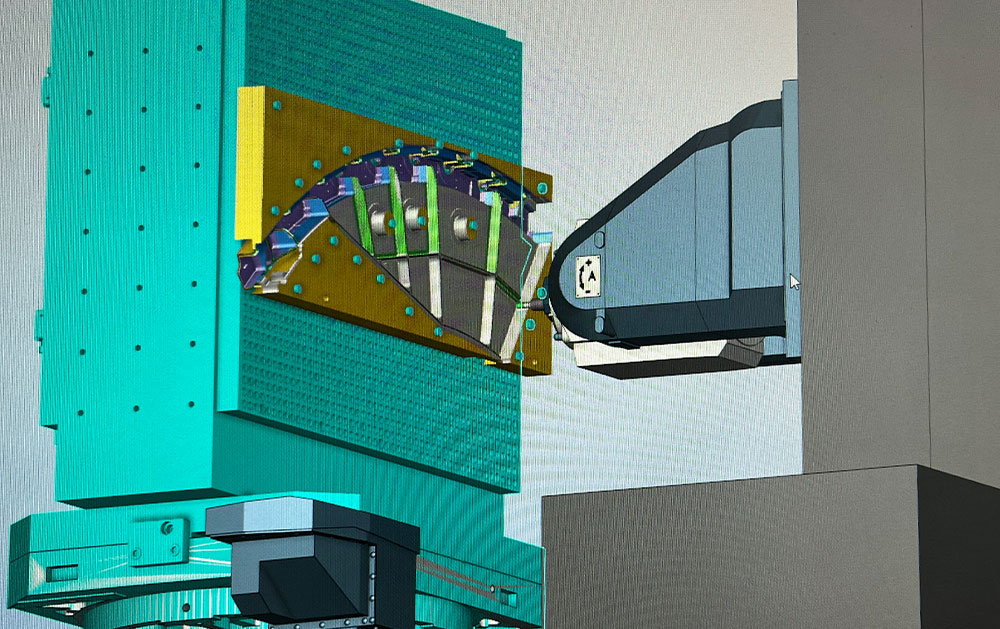

Engineering Software

Here at Precision Machine of Savannah, we utilize a variety of advanced software, up to date with the latest revisions, to ensure precision and efficiency throughout the manufacturing process. This process begins in Catia to interrogate customer-supplied 3D models, allowing us to fully understand complex geometries and prepare accurate machining strategies. Our engineering team then develops CNC programs using Mastercam, a powerful and versatile CAM software, that enables us to create toolpaths optimized for high-performance machining. To guarantee program accuracy and protect valuable equipment, we simulate all CNC programs in Vericut before production. This critical step allows us to verify toolpaths, detect potential collisions, and optimize machining processes, ensuring the highest standards of quality and reliability that our aerospace clients demand.

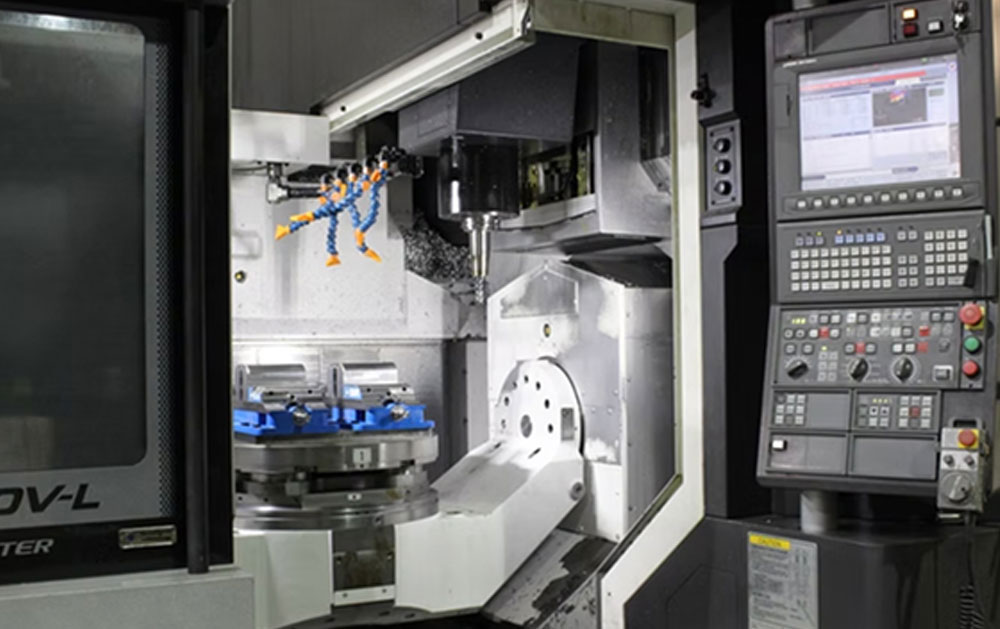

Machining Equipment

At Precision Machine of Savannah, we specialize in precision aerospace machining powered by the latest advancements in manufacturing technology. Our facility is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machines, enabling us to produce highly complex components with exceptional accuracy and efficiency. From intricate prototypes to high-volume production runs, our multi-axis capabilities allow for reduced setup times, tighter tolerances, and superior surface finishes. We pair our cutting-edge machinery with advanced software tools like Catia, Mastercam, and Vericut to ensure seamless integration from tooling design to final product. With a focus on innovation, quality, and reliability, PMS is committed to meeting the demanding needs of the aerospace industry, delivering precision parts that perform in the most critical environments.

Inspection Equipment

Precision Machine of Savannah transfers Digital Product Definition (DPD) into PC-DMIS software to create the programs for the CMM’s by using Direct CAD Interface (DCI). This allows our CMM programmers the ability to inspect parts based off of the customer supplied engineering and ensures all key characteristics are measured in a single setup. The software used in our inspection lab is covered under our OEM’s MyCare program, this includes hardware & software maintenance and customer support which ensures that you have minimized unplanned down time. The latest upgrades are implemented and utilized for maximum productivity and the most accurate programming capabilities.