ABOUT US

Founded in 1988, Hugh Kesler started Precision Machine of Savannah (PMS) in his backyard with a Bridgeport milling machine and a lathe.

In 2006, Hugh Kesler started Precision Protective Coatings adjacent to their PMS facility and provides NADCAP approved processing to allow quick turnaround for multiple coating requirements.

Technologies We Use

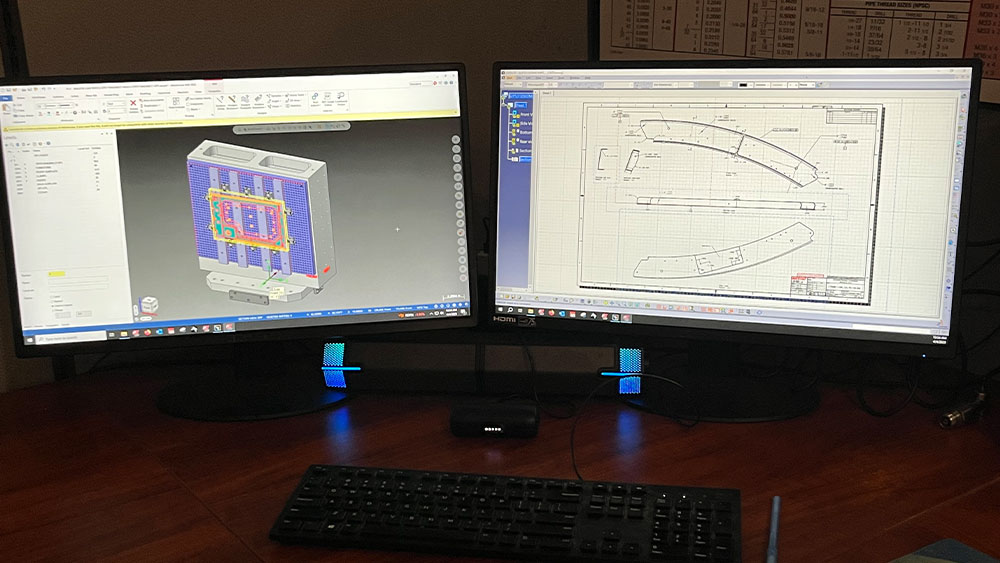

ENGINEERING SOFTWARE

Precision Machine of Savannah uses cutting-edge software to deliver precise, efficient aerospace manufacturing. From analyzing 3D models in Catia to programming in Mastercam and simulating in Vericut, we ensure quality, reliability, and collision-free performance every step of the way.

Certifications

Precision Machine of Savannah maintains a Quality Management System that is certified and complies with all the requirements of AS9100D when they are applicable within the determined scope of the QMS. This also includes ISO 9001:2015 Quality Management System requirements and specifies additional requirements for a quality management system for the Aviation, Space and Defense Industry.